Model Water Level Control System

Undergraduate Project

Principal Supervisors

- Eng. (Mr.) Wesley Rathnakumar

Group Members

- Indushan Senavirathna

- Selvakulaveerasingam T.

- Shafan A.M.M

- Thapothanan T.

- Tharanya M

- Thavanesan T

- Vinothprasanth W.

- vithurshan S.

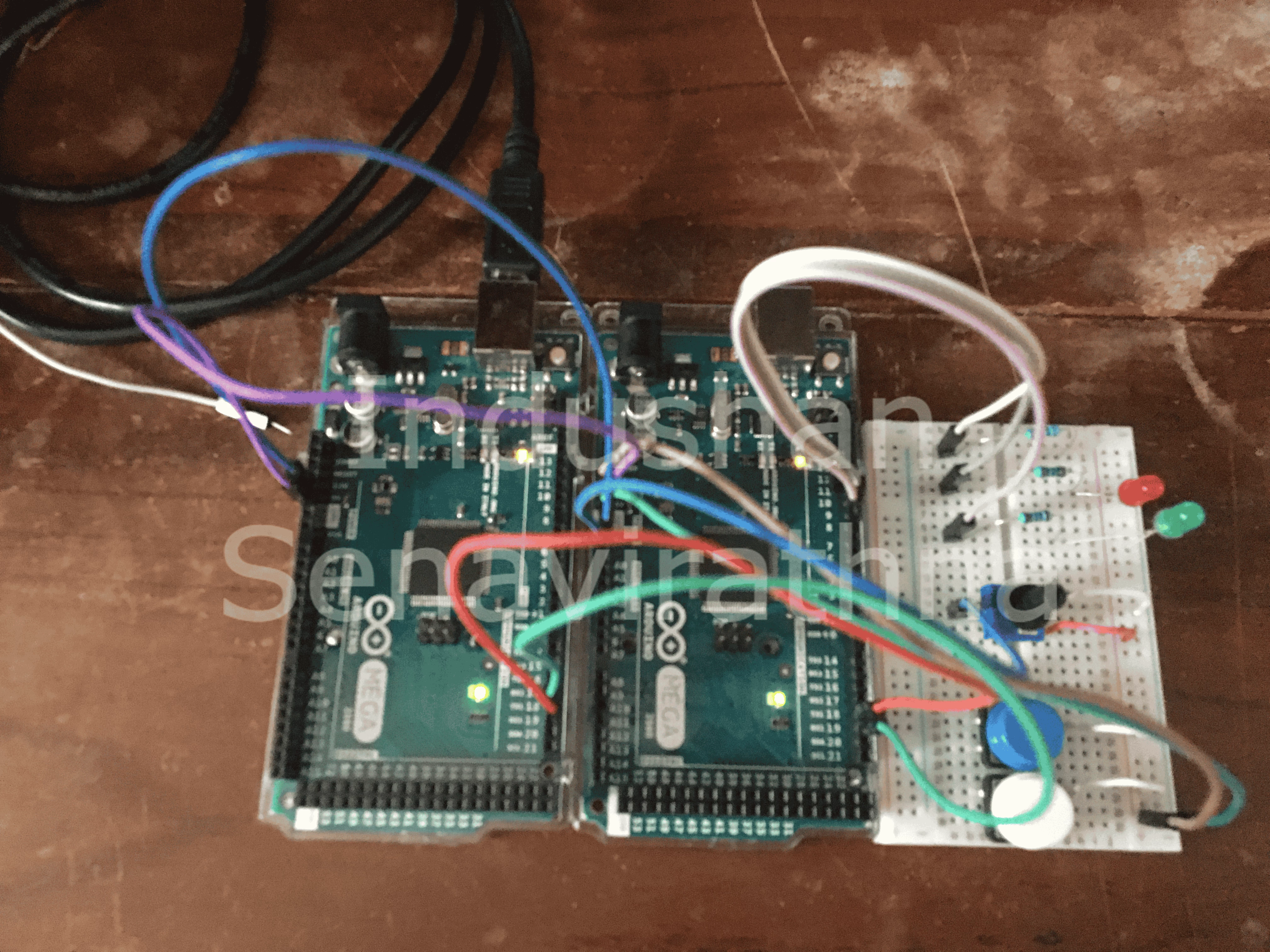

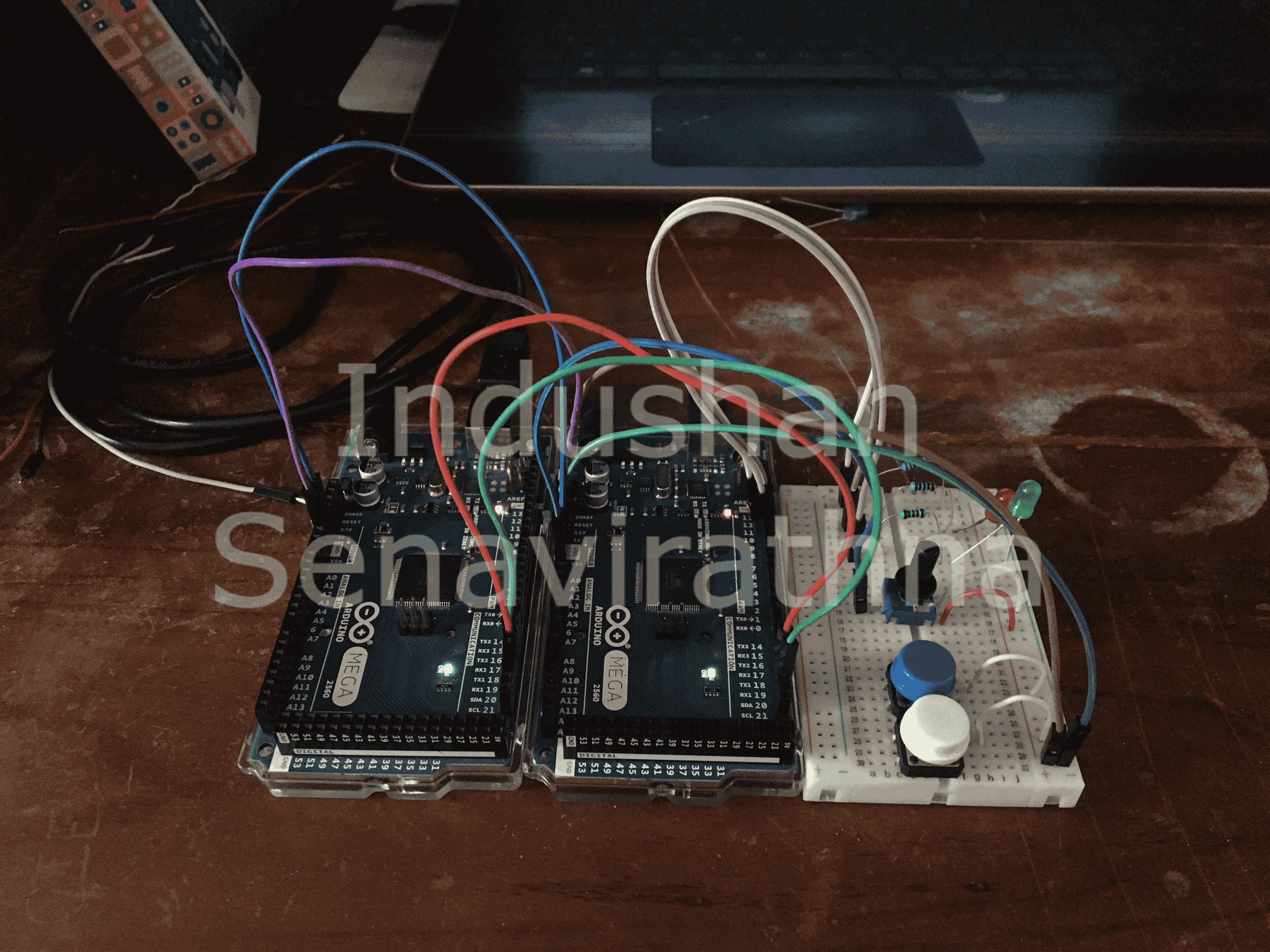

This project describes the design and implementation of a communication protocol using the Modicon Modbus Protocol for establishing master-slave communication. The project involves controlling two motors (A and B) to fill a tank based on water level measurements. The system utilizes RTU framing and UART communication over a baud rate of 9600 bits-per-second. Error packet timeouts are implemented according to the protocol. The motors are modeled using LEDs for visual indication, while water level is indicated using a potentiometer. The report presents the system description, protocol design and implementation details, device modeling approach, experimental results, observations, and a discussion of design decisions and challenges faced during implementation. The conclusion evaluates the effectiveness of the designed communication protocol and suggests potential improvements.

- Design and implementation of a communication protocol: The project aims to design and implement a communication protocol using the Modicon Modbus Protocol for establishing master-slave communication between microcontrollers. The project involves developing the necessary logic and algorithms to ensure effective communication and control between the master and slave devices.

- Motor control based on water level: The project focuses on controlling two motors (A and B) to fill a tank based on water level measurements. The designed system includes logic and algorithms to accurately control the motors based on the specified conditions, such as motor switching, level monitoring, and motor operation count management.

- Baud rate selection and timeout implementation: The project involves selecting an appropriate baud rate for the serial transmission in the system. The baud rate of 9600 bits-per-second is chosen for reliable communication. Additionally, timeouts are implemented to handle error packets as per the Modbus protocol specifications.

- Understanding and application of Modbus protocol: The project requires a comprehensive understanding of the Modicon Modbus Protocol commonly used in PLCs and SCADA systems. The protocol's principles, message framing using RTU framing, and implementation over UART communication are applied to establish communication between the master and slave devices.

- Device modeling and visualization: The project involves modeling the motors using LEDs for visual indication and utilizing a potentiometer to represent the water level. This allows for a practical representation of the system components, enabling better understanding and visualization of their statuses and behaviors.

- Experimental validation and analysis: The project includes conducting experiments to validate the implemented system and its functionalities. The experimental results are analyzed and evaluated to assess the performance and effectiveness of the designed communication protocol, motor control logic, baud rate selection, and timeout implementation.

- Documentation and project presentation: The project requires the creation of detailed documentation, including the project requirements, design specifications, implementation details, experimental results, and analysis. Additionally, a project presentation may be prepared to showcase the project's objectives, methodologies, and outcomes.

Skills

- Communication protocol design (Modicon Modbus Protocol)

- Microcontroller programming

- Motor control algorithms

- Serial communication (UART)

- Baud rate selection (9600 bits-per-second)

- Error handling and troubleshooting in Modbus Protocol

- RTU framing in Modbus Message Framing

- Device modeling and visualization (LEDs for motors, potentiometer for water level)

- Data framing and packet handling in Modbus Protocol

- Control system design for motor operation and water level monitoring

- Understanding and implementing the Modicon Modbus Protocol commonly used in PLCs and SCADA systems

- Experimentation with the implemented system

- Data analysis of experimental results

- Technical documentation (for lab report or project documentation)

- Presentation skills for showcasing the project objectives, methodologies, and outcomes

- Problem-solving and critical thinking in the context of protocol implementation and motor control

- Time management and project planning to meet project milestones and deadlines.